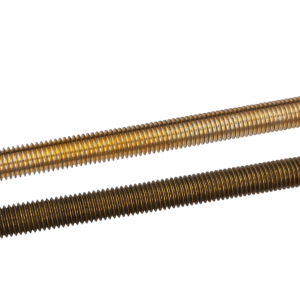

304 stainless steel butterfly washer DIN6796 bowl shaped anti-slip gasket

Product Photos and Information

| Name | Spring Washers | Materials | Carbon Steel/Stainless Steel |

| Standards | DIN ISO ANC BSW JIS etc. | Strength level | 4.8 8.8 etc. |

| Size | M4-M130 | Surface finish | ZPBLACKHDG etc. |

| Length | / | Samples | Available |

Product Standards

| Disc Spring DIN 2093 | ||||||||||||||||

| Specification | 8 | 10 | 12.5 | 14 | 16 | 18 | 20 | 22.5 | 25 | 28 | 31.5 | 35.5 | 40 | 45 | 50 | |

| d 1 | Min = Nominal (H12) | 4.2 | 5.2 | 6.2 | 7.2 | 8.2 | 9.2 | 10.2 | 11.2 | 12.2 | 14.2 | 16.3 | 18.3 | 20.4 | 22.4 | 25.4 |

| maximum value | 4.32 | 5.32 | 6.35 | 7.35 | 8.35 | 9.35 | 10.38 | 11.38 | 12.38 | 14.38 | 16.48 | 18.51 | 20.61 | 22.61 | 25.61 | |

| d 2 | max = nominal (h12) | 8 | 10 | 12.5 | 14 | 16 | 18 | 20 | 22.5 | 25 | 28 | 31.5 | 35.5 | 40 | 45 | 50 |

| minimum | 7.85 | 9.85 | 12.32 | 13.82 | 15.82 | 17.82 | 19.79 | 22.29 | 24.79 | 27.79 | 31.25 | 35.25 | 39.75 | 44.75 | 49.75 | |

| t | 0.4 | 0.5 | 0.7 | 0.8 | 0.9 | 1 | 1.1 | 1.25 | 1.5 | 1.5 | 1.75 | 2 | 2.25 | 2.5 | 3 | |

| t 1 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| h 1 | 0.2 | 0.25 | 0.3 | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.55 | 0.65 | 0.7 | 0.8 | 0.9 | 1 | 1.1 | |

| h | 0.6 | 0.75 | 1 | 1.1 | 1.25 | 1.4 | 1.55 | 1.75 | 2.05 | 2.15 | 2.45 | 2.8 | 3.15 | 3.5 | 4.1 | |

| Gasket Type | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| Specification | 56 | 63 | 71 | 80 | 90 | 100 | 112 | 125 | 140 | 160 | 180 | 200 | 225 | 250 | ||

| d 1 | Min = Nominal (H12) | 28.5 | 31 | 36 | 41 | 46 | 51 | 57 | 64 | 72 | 82 | 92 | 102 | 112 | 127 | |

| maximum value | 28.71 | 31.25 | 36.25 | 41.25 | 46.25 | 51.3 | 57.3 | 64.3 | 72.3 | 82.35 | 92.35 | 102.35 | 112.35 | 127.4 | ||

| d 2 | max = nominal (h12) | 56 | 63 | 71 | 80 | 90 | 100 | 112 | 125 | 140 | 160 | 180 | 200 | 225 | 250 | |

| minimum | 55.7 | 62.7 | 70.7 | 79.7 | 89.65 | 99.65 | 111.65 | 124.6 | 139.6 | 159.6 | 179.6 | 199.54 | 224.54 | 249.54 | ||

| t | 3 | 3.5 | 4 | 5 | 5 | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | ||

| t 1 | - | - | - | - | - | - | - | 7.5 | 7.5 | 9.4 | 9.4 | 11.25 | 11.25 | 13.1 | ||

| h 1 | 1.3 | 1.4 | 1.6 | 1.7 | 2 | 2.2 | 2.5 | 2.6 | 3.2 | 3.5 | 4 | 4.2 | 5 | 5.6 | ||

| h | 4.3 | 4.9 | 5.6 | 6.7 | 7 | 8.2 | 8.5 | 10.6 | 11.2 | 13.5 | 14 | 16.2 | 17 | 19.6 | ||

| Gasket Type | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | ||

| ①,Material | ||||||||||||||||

| a) Made of steel as specified in DIN EN10083, DIN EN10089 or DIN EN10132-4. Carbon steel should only be used to make Class 1 springs. Modulus of elasticity of steel E=206000MPa | ||||||||||||||||

| b) Modulus of elasticity and strength properties of other materials (eg spring stainless steel according to DIN EN 10151, copper alloys (spring bronze) according to DIN EN 1654) may vary. | ||||||||||||||||

About Us

Dabang Fasteners is a wholly-owned subsidiary of Hebei Chengyi Engineering Materials Co., Ltd.

Our parent company has 21 years experience in fastener production and is ISO9001 ISO14001 ISO45001 SGS certified.

We focus on providing customers with competitive products that meet user needs.

--- Factory price, saving 15-30% of the middleman price difference.

--- exporting to 154 countries, accumulatively serving 1800+ customers, rich export experience

--- 5000 tons in stock, up to 3000 tons per month, average delivery time 7-20 days.

--- After-sales team of 25 people, solve all after-sales problems

0 Risk Commitment

--- If the product quality and packaging problems are found after receiving the goods,

help solve the problem and unconditionally compensate the loss within 30 days.

Our added value

--- In China, provide you with free factory inspection services.

Factory Introduction

Production Process

Packing and Shipping

Certificate

Exhibition/partner Photos

sofina@db-cyfastener.com

sofina@db-cyfastener.com +8615027927592

+8615027927592 8615027927592

8615027927592 8615027927592

8615027927592 8615027927592

8615027927592